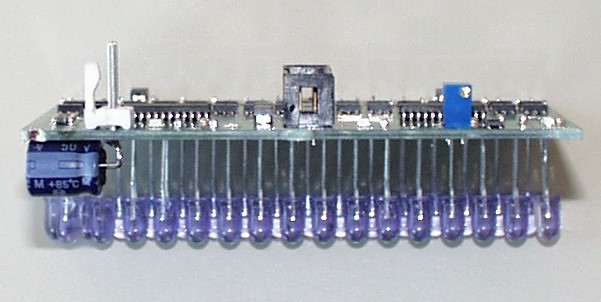

Fast Prototype technology is a method of assembling electronic components onto a printed circuit board (PCB) by inserting the component leads through holes in the board and soldering them to pads on the opposite side. This can be done manually or with automated machines.

Fast Prototype Technology is a process aimed at quickly creating functional prototypes or small batches of electronic products for evaluation,testing, validation, and design verification purposes. This technology allows engineers and designers to rapidly develop and refine their electronic designs before committing to full-scale production. Key points about Fast Prototype Technology include:

-

Rapid Turnaround: It emphasizes speed and agility in producing prototypes, typically with shorter lead times compared to traditional manufacturing.

-

Smaller Quantities: It is often used for producing a limited number of prototype boards or a small batch of units

-

Flexible Design Changes: It allows for easy modifications and iterations in the design to refine the product before mass production.

-

Use of Various Prototyping Methods: Fast Prototype Technology may involve methods like PCB prototyping, 3D printing, and other rapid prototyping techniques