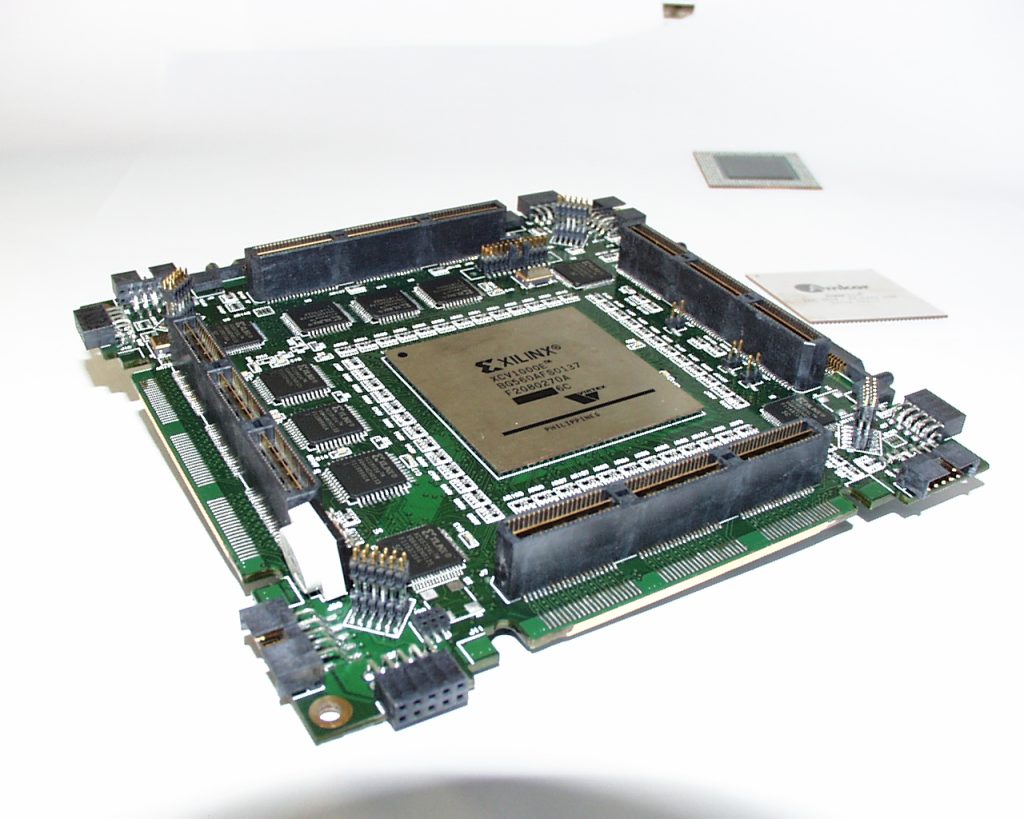

Printed circuit boards (PCBs) are essential components of most electronic products. They provide a way to connect internal electronic components together by using conductive tracks etched into a non-conductive substrate. PCBs can be single-layer, double-layer, or multi-layer, depending on the complexity of the electronic device.

Single-layer PCBs are used for simple electronic devices, while multi-layer PCBs are used for complex devices such as computer motherboards and smartphones. Multi-layer PCBs have a higher component density than single- or double-layer PCBs because they allow circuit traces to be placed on the inner layers of the board. This frees up space on the surface of the board for components.